Understanding Pressure Reducing Valves

Posted on May 27, 2020

May, 2020

Most of us who live in the Metro Detroit area enjoy the convenience of clean, reliable drinking water at the turn of a faucet. The local municipalities that we live and work in deliver water to our plumbing systems through vast underground pipe networks.

WHERE DOES CLEAN WATER COME FROM?

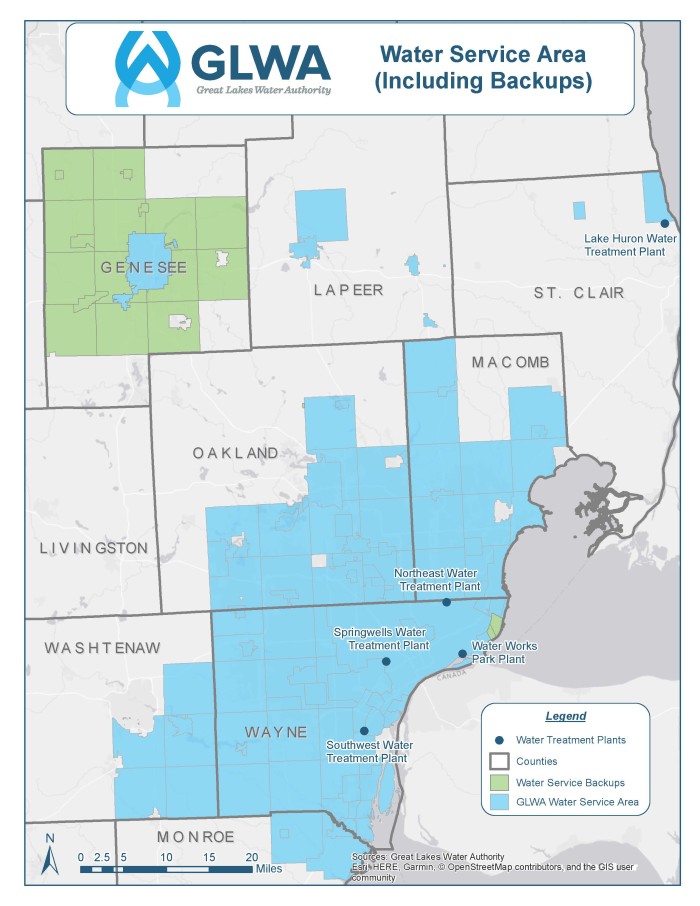

But where does your local municipality get their water? If you live in Macomb, Oakland, or Wayne counties, chances are your water is treated and sent to your community by the Great Lakes Water Authority (GLWA). The map to the right shows all the areas in southeast Michigan that GLWA sends treated drinking water.

GLWA has the capacity to treat up to 1.7 billion gallons of water per day. However, large amounts of energy are required to deliver large volumes of water to customers spread over these vast areas. GLWA must use high pressures in large diameter water mains to force all of this water such long distances.

Our local municipalities also rely on the pressure provided by GLWA in order to force the water from their mains into our homes and businesses. However, this means that these communities are also exposed to the high pressures and, sometimes, pressure surges in GLWA transmission pipes.

While they are necessary for water transmission, these high pressures can have negative effects. For example, the high pressures and occasional pressure surges place unnecessary stress on the system’s water mains and fittings leading to increased risk of water main breaks. Higher pressures also result in increased water consumption. The higher the pressure, the more flow is forced into the system which costs communities more money, and in turn, it costs you, the end user, more money.

PRESSURE REDUCING VALVES

Communities have recently been protecting their systems from these high pressures by installing Pressure Reducing Valves (PRV’s). PRV’s work by maintaining a desired pressure downstream of a high-pressure zone. In this case, communities install PRV stations directly downstream of their connections to the GLWA system. This allows the GLWA system to continue operating at high pressures and the community’s systems to operate at more efficient pressures. PRV’s also provide protection from pressure surges that can occur when pumps shut off suddenly or valves are operated improperly.

As a testament to their reliability, Biren Saparia, the Systems Operation Manager at GLWA, estimates that about 60% of GLWA’s customer meters have PRV’s. At AEW we have worked closely with Engineered Fluids, a custom engineered water systems manufacturer, to help improve our Client’s water distribution systems. We have partnered with Engineered Fluids to install approximately 30 of these PRV’s in communities that we represent throughout the Greater GLWA service area.

HOW DO PRV’S WORK?

Between Fraser, Roseville, and Clinton Township, 5 consecutive PRV’s have been proposed for construction over the next year within just a 2 mile stretch along 14 Mile road.

With the many PRV’s installed over the recent years, one thing I’ve often heard in discussions surrounding PRV stations is “I wonder how this is going to affect other communities. That pressure has to go somewhere.” While this is technically true, we can look at this, in depth, using a simplified example with engineering calculations.

The key to understanding the example below are the following principles of Fluid Dynamics:

- Water pressure decreases over long distances due to the friction experienced between the flowing water and the pipe walls

- The PRV’s reduce the overall water consumption

- The pressure loss due to friction is dependent on the velocity of the water in the pipes

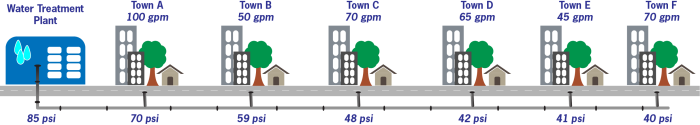

In our example, we have a hypothetical system made up of 6 towns along a single pipeline served by a treatment plant. The treatment plant must pressurize the water main to a level of 85 psi in order to provide the most distant community, Town F, with its operating pressure of 40 psi. Each town’s water consumption and water pressure is shown in the figure below in gallons per minute (gpm) and pounds per square inch (psi). Without any PRV’s the total consumption in this system is 400 gpm. As you can see, the pressure decreases from one town to the next as you move further from the treatment plant. This is principle #1 in action.

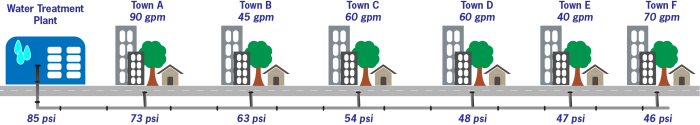

Towns A through E then decide to install PRV’s for their many benefits described above. After installation, we assume, based on principle #2, that the PRV’s reduce the consumption in the system to 365 gpm, an overall reduction of about 9%. The Post-PRV consumptions and water pressures for each town are shown in the figure below.

When the consumption is reduced by the various PRV’s, the flow rate is decreased which means the velocity is also decreased. According to principle #3, this reduction in velocity means that less pressure is lost along the pipeline. Consequently, the pressure experienced by Town F is now higher than it was before the PRVs were installed. Like many engineers have postulated, “that pressure has to go somewhere.”

The higher pressures experienced at Town F could cause the issues we previously described. It is possible the systems may not be equipped to handle the new higher pressures. Town F could be expected to experience higher consumptions due to the higher pressure, increasing costs.

However, our post-PRV scenario assumes that the treatment plant is still pressurizing the system to 85 psi. In reality, the treatment plant is capable of pressurizing the system at lower levels. Based on our example, the treatment plant could reduce the pressure to 79 psi in order to provide the same pressure that Town F experience before the PRV’s. This means that the treatment plant can save energy costs by operating fewer pumps. This lower pressure also puts less strain on the GLWA pipeline.

This simple example illustrates how PRV’s are a true win-win. Not only do they provide their local communities with additional safety and reliability, but they also provide a significant benefit to the provider, in our case the GLWA. Best of all, the savings are passed down to the end users.

Born and raised in southeast Michigan, Ross graduated from U of M in 2014 where he studied Civil Engineering with a background in Hydraulics and Hydrology. Ross currently specializes in general-civil and municipal engineering projects, and is heavily involved in project management. Obtaining his professional engineering license in 2019, Ross’ experience ranges from water reliability and hydraulic/hydrologic studies to infrastructure design of sewers, water mains, pressure reducing valve stations, and roads. In the limited time that he isn’t working on his house, Ross spends as much time as possible up north or on the water. Ross enjoys outdoor activities like golfing, fishing, boating, and skiing. He also enjoys playing sports like hockey and tennis while he still can. Outside of his amateur athletic ambitions he’s also a passionate fan of local college and professional sports.